![]()

Christopher Spencer’s Horizontal Shot Tower

By Stephen F. Blancard

The old saying “Necessity is the mother of invention” was never truer than during the mid-1800’s. The Industrial Revolution was well underway by the time the war for southern independence had begun. A young man by the name of Christopher Miner Spencer, born June 20, 1833 saw a need and proceeded to fill it. In his early years he worked in Samuel Colt’s armory where he gained valuable experience in the arms-making trade.

With the advent of self-contained metallic cartridges such as Smith and Wesson’s .22 short rimfire and the .44 Henry rimfire, Spencer foresaw great changes to come in the small arms industry. By the late 1850’s his inventive mind had begun to conceive not only a reliable breechloader, but a repeating one at that. He was fully aware of the deficiencies of other early repeaters such as the Volcanic with its “Rocket Ball” cartridge and Colt’s revolving rifle. But by using a completely self-contained metallic cartridge, their faults would be eliminated.

What he envisioned was a lever-actuated rolling block action. Cartridges were fed through a tubular magazine in the buttstock. The inner magazine tube could be withdrawn from the butt for loading. Similar in function to the modern .22 cal. rifle with an under barrel magazine. Capacity was seven rounds.

Spencer’s first model was believed to have been completed in 1859. His friend R.S. Lawrence, of the firm of Robbins and Lawrence were early contractors of Sharps rifles and carbines. So it is not surprising that some lock parts with interchange with the Sharps. Spencer’s first arms were in .36 and .44 rimfire. These used a smaller frame than the later military models. Spencer obtained his first patent on March 6, 1860. A second patent issued July 29, 1862 contained several improvements to the original design.

Spencer was anxious to arm the Union with this rifle. However, he son ran headlong into the thick red tape of the Federal government. Fortunately, he was able to obtain an interview with president Lincoln. Knowing that Lincoln was a man who would appreciate his rifle, he decided to go straight to the top. The following is a quote directly attributed to Christopher Spencer concerning his interview with the President.

“On the 18 of August, 1863, I arrived at the White House with rifle in hand, and was immediately ushered into the executive room. I found the president alone. With brief introduction I took the rifle from its case and presented it to him. Looking it over carefully and handling it as one familiar with firearms, he requested me to take it apart to show the “inwardness of the thing.” It was soon dissected, laid on the table before him. After a careful examination and his emphatic approval, I was asked if I had any engagement for the following day. When I replied that I was at his command, he requested that I “Come over tomorrow at 2 o’clock, and we will go out and see the thing shoot.”

Arriving at the appointed time, I found all in readiness to proceed to the shooting place, which was about where now stands the Washington Monument. Accompanying us was his son, Robert, and one of the officers of the Navy Department who carried the target and rifle, with the ammunition. Arriving at a point opposite the War Department the President requested Robert to go over and ask Mr. Stanton to come over and see this new gun fired. Robert soon returned and reported Mr. Stanton too busy to attend. “Well,” says the President, in his humorous way, “they do pretty much as they have a mind to over there.”

While we were waiting for Robert, Mr. Lincoln discovered that one of the pockets of his black alpaca coat was torn open. Taking a pin from his waistcoat, he proceeded to mend it, remarking, “It seems to me that that don’t look quite right for the Chief Magistrate of this Mighty republic, Ha! Ha! Ha!”

Arriving at the shooting ground, Mr. Lincoln, looking down the field, said, “It seems to me, I discover the carcass of a colored gentleman down yonder,” and ordered the target placed so as to avoid accidents. The target was a board about six inches wide, and three feet long, with a black spot near each end. The rifle contained seven cartridges. Mr. Lincoln’s first shot was low, but the next his the bull’s eye, and the other five were close around it. “Now,” says he, “we will let the inventory try it.” Being in almost daily practice, I naturally beat the President a little. “Well,” he said, “you are younger than I am, have a better eye, and a steadier nerve.”

The end of the board which the President had shot was cut off by the Navy official, and handed to me when we parted on the steps of the White House. I kept it until 1883 when at the request of one of the staff of the Army and Navy Journal, it was sent to Springfield, Illinois, to be placed in the collection of relics.

Some authorities question whether this interview was in 1862 or 1863. It seems more likely that it was 1862. Since by the spring of 1863 Spencer's were in widespread use. It was noted that the President was quite impressed with young Spencer’s rifle. What effect the presidential test had on future government orders is hard to determine.

The first recorded use of a Spencer in battle was by a personal friend of Christopher Spencer named Sgt. Francis O. Lombard. Lombard used it in a skirmish near Cumberland, Maryland on October 16, 1862. The first official use of the Spencer was at the battle of Gettysburg.

Initially rifles

were issued to the cavalry. But the shorter carbine soon proved its superiority

for mounted troops. From Jan. 1, 1861 to June 30, 1866 the Federal government

purchased 94,196 carbines, 13,171 rifles and more than 58,000,000 cartridges.

The wartime Spencer was chambered for the No. 56 Spencer rimfire cartridge, also

called the .56-56 Spencer. Rifles had a 30” round barrel, full forend retained

with three iron bands. About 700 rifles were ordered by the Navy and made to

take the sword bayonet. Spencer is though to have actually made about 1,000 on

this production run. Probably selling the remaining 300 to the public. All other

rifles procured by the government from Spencer were made to take the socket

bayonet. The wartime Spencer carbine had a 22” barrel, short forend retained

with a single iron band and spring. From the receiver back, it is the same as

the rifle. Approximately 50,000 war model carbines were produced. By the end of

the war the Spencer carbine had pretty well established itself as the best arm

suited for cavalry use.

Spencer was chambered for the No. 56 Spencer rimfire cartridge, also

called the .56-56 Spencer. Rifles had a 30” round barrel, full forend retained

with three iron bands. About 700 rifles were ordered by the Navy and made to

take the sword bayonet. Spencer is though to have actually made about 1,000 on

this production run. Probably selling the remaining 300 to the public. All other

rifles procured by the government from Spencer were made to take the socket

bayonet. The wartime Spencer carbine had a 22” barrel, short forend retained

with a single iron band and spring. From the receiver back, it is the same as

the rifle. Approximately 50,000 war model carbines were produced. By the end of

the war the Spencer carbine had pretty well established itself as the best arm

suited for cavalry use.

After the war, Springfield Armory altered approximately 11,000 war model carbines. The barrels had liners installed to accept the new .50 cal. cartridge. A device know as the “Stabler Cut Off” was added which enabled the gun to be used as a single shot, keeping the magazine in reserve. This was a small piece very similar to a wing nut. It was mounted on the trigger plate just ahead of the trigger. When positioned lengthwise it prevented the breech block from opening far enough for the magazine to fee a fresh cartridge. When turned sideways it allowed the block to open fully.

In 1865 Spencer came out with a new version appropriately called the Model 1865. This was essentially the same as the war model, except that it was chambered for the new .56-50 cartridge. Production of this model was about 23,000 pieces of which about half are fitted with the Stabler Cut Off. These are marked on the barrel breech “M 1865”. The Model 1865 was also made under contract by the Burnside Rifle Company. Burnside production was approximately 34,000 carbines. The only variation from Spencer made guns are that these have three groove rifling instead of six groove and are marked as made by the Burnside Rifle Company.

The Model 1867 soon followed. This again was almost the same as its predecessor. However, many of these were fitted with the “Spencer Patent Magazine Cut Off”. This was an extra wide device in place of the usual narrow cartridge ejector. Pivoting the top prevents the breech block from traveling rearward enough to accept the next cartridge from the magazine. Marked on barrel breech “M 1867”.

Spencer’s last version was simply called the “New Model”. It was identical to the Model 1867, with the exception of “N.M.” marked on the barrel breech.

In 1871 Springfield Armory altered 1,108 Burnside made Spencer carbines to infantry rifles. These had their barrels replaced with 32 ½” round barrels chambered for the .56-50 cartridge. A full forend was added, retained with two iron bands. (All Spencer made rifles have three iron bands.) The Stabler Cut Off was added as well. All Spencer rifles and carbines altered by Springfield Armory will have three groove rifling.

A relatively small number of sporting rifles were made. Some were made on the military action. But others were made using a smaller, scaled down receiver. These were occasionally chambered for the .56-46 Spencer rimfire cartridge. In prime condition these command a premium price. I direct the reader to “Flayderman’s Guide To Antique American Firearms” for a more detailed description of the various models.

The Spencer had proven itself in combat during the war and then again in the Indian campaigns. Despite its proven record it was withdrawn from service in 1873. The Army had changed its mind and decided that the single shot Model 1873 “trapdoor” Springfield was better suited to their needs. Most troopers were reluctant to turn in their repeaters for single shots. But orders were orders. Perhaps the Spencer was ahead of its time. In its heyday, during the war there no doubt were times when Confederate troops armed with old smoothbore muskets faced Federal troops armed with the repeating Spencer. The comparison is truly dramatic. Certainly the courage of the Southerners cannot be denied. The death dealing Spencer soon earned the sobriquet “Horizontal Shot Tower”.

Spencer’s diligent efforts during the war soon proved to be his undoing. After the war there was a vast surplus of arms available to the public. Spencer just could not compete. He had produced himself right out of the market. By 1869 the Spencer Repeating Rifle Company was in bankruptcy. All its assets were purchased at auction by the shrewd Oliver Winchester, who immediately turned a profit by selling off Spencer’s machinery.

Christopher Spencer continued to be active in manufacturing. He later patented one of the first slide action shotguns made in America. His inventive genius was not limited to just firearms. Spencer’s innovations in the machine tool industry are still used today. Christopher Miner Spencer spanned the era from flintlock to machine gun, living to the age of 89. He died on January 14, 1922.

From 1860 to 1869 almost 140,000 Spencer rifles and carbines were made in military configuration. A relatively small number of sporting rifles were made, certainly not many. I believe it would be safe to say that total Spencer production did not exceed 145,000 pieces.

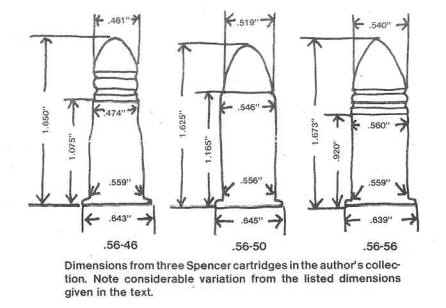

Identification of the various Spencer cartridges has always been a problem due to their unusual designation. The first cartridge designed by Spencer was simply called the “No. 56 Spencer rimfire”. At the time this was fine. There were very few other cartridges available. Later it was called the .56-56 Spencer. The “56” represents the diameter of the cartridge at its base, .560”. The second number is the neck diameter. In this instance it simply means it is a straight case. The listed dimensions are as follows. Case length .875”, rim diameter .645”, bullet diameter .550”. But as usual there is quite a bit of variation in these. Bullet weight was 350 grains. This was backed by 45 grains of black powder, giving a muzzle velocity of about 1200 fps. While not equivalent to the service load, it was quite adequate at short range.

By 1864 Springfield Armory had designed a new cartridge. This was designated the .56-50 rimfire. In this case the “50” does not really represent neck diameter, but rather a rough statement of bore size. The listed dimensions are a s follows. Base diameter is the same as the .56-56. Neck diameter .543”, rim diameter .639”, bullet diameter .512”, case length 1.156”. This was loaded with a 350 grain bullet and 45 grains of black powder, giving a muzzle velocity of about 1230 fps. It could penetrate almost a food of soft pine at 15 feet.

Now to add to the confusion, Christopher Spencer did not approve of Springfield Armory’s .56-50. He believed it had an excessive crimp. By designing the cartridge with a bottleneck instead of the deep crimp, he felt accuracy could be improved. Thus in 1866 the .56-52 was born. Although very similar to the .56-50, its dimensions are slightly different. The listed dimensions are as follows.

Base diameter is again .560”, neck diameter .547”, rim diameter .642”, case length 1.020”, slightly shorter than the .56-50. Bullet diameter .525”. This is .013” larger than the .56-50 bullet. Since this was primarily a sporting cartridge it was loaded with either a 340, 386 or a 400 grain bullet and backed by 45 grains of black powder.

The .56-50 and the .56-52 are said to be interchangeable despite the difference in dimensions. Considering the wide tolerances acceptable 120 years ago, this is understandable. As an example, the bore of my own 1865 model Spencer carbine has a groove diameter of .514”. I know of a Burnside made Spencer carbine who’s groove diameter measures .524”. Yet both these carbines are chambered for the same cartridge. Accuracy would vary quite a bit depending on the cartridge selected.

The last Spencer cartridge is known as the .56-46 Spencer rimfire. It was used almost exclusively in the rare sporting rifles. This was one of the first true bottleneck cartridges. The listed dimensions are as follows. Base diameter .558”, rim diameter .641”, neck diameter .478”, case length 1.035”, bullet diameter have been noted between .460 and .488. This cartridge was usually loaded with a 330 grain bullet and 45 grains of black powder giving a velocity of about 1200 fps. Ballistics were improved over the larger cartridges and recoil was reduced by the lighter bullet.

All these cartridges were loaded by a number of different companies between 1860 and 1920. Due to the leeway in tolerances, the dimensions of these cartridges vary considerably. In some cases it is all but impossible to tell the differences between a .56-50 and a .56-52.

Enough facts and figures. You say you have a Spencer and would like to shoot it? Well, fortunately there are several alternatives. Let’s start with the simplest.

The easiest and least expensive way is by the use of reloadable rimfire cases. These are available from Dixie Gun Works (P.O. Box 130, Union City, TN 38261). Part number is KA 0304. these cases are made from solid brass stock and are very durable. In the bottom of the case is an offset chamber made to hold a .22 short case (with bullet and powder removed). This is the “primer”. Just put your .22 short case in the chamber, pour in your charge of black powder or pyrodex and seat your bullet. The outside dimensions of this case are very similar to the .56-56. Inside diameter is about .520”. Due to the wall thickness (approximately .020”) they are recommended and most suitable for use in guns chambered for the .56-50 and .56-52. Although I have not tried it, I think that these cases could be adapted for use in guns chambered for the .56-56. Since these cases are quite thick, the neck should be reamed from the inside. This would allow the use of a larger bullet. How much reaming is necessary will depend on the actually bore size of the rifle it will be used in. This would be practical only up to a certain point. Opening the neck to much would weaken it.

The .56-46 poses a different problem. This is a bottleneck cartridge. With a bit of work these reloadable cases can be adapted for use.

Again due to the thickness of these cases they will have to be thinned down enough to be worked. This thinning will have to be to a point just below where the shoulder will begin. A chamber cast will be necessary to determine where the shoulder will go. A sizing die will be required to reduce the neck to the proper diameter and create the shoulder. These will end up being a little short, but by seating the bullet a little further out they should work fine.

There is one drawback to using these reloadable cases. Since the primer (.22 short case) is located on one side of the case, they have to be carefully placed in the chamber with the primer in the three o’clock position. It would be almost impossible to get seven cartridges properly oriented in the magazine. Thus, when using these cartridges the gun would be reduced to single shot status.

Another alternative and one which is becoming more and more popular is to convert the gun to centerfire. This requires a bit more work and expense. But if you intend on shooting your Spencer regularly, it is probably the best way to go.

In the December 1967 issue of Shooting Times there is an article by Mr. E.V. Hathaway entitled “Shoot That Spencer”. In his article Hathaway gives precise instructions on how to convert a spare upper breech block to centerfire. Two things are required for this. One is a spare upper breech block (you don’t want to alter your original). These used to be easy to find. But in recent years they’ve become very scarce. The second is access to a milling machine or a gunsmith with one who would be willing to do the work. I highly recommend obtaining a copy of his article if you wish to undertake such a project. Hathaway has done a lot of work developing his conversion. If you have the equipment and the ability, I recommend it.

The third alternative is to purchase a centerfire breech block. This has been made possible just recently by the folks at S & S Firearms (74-11 Myrtle Avenue, Glendale, NY 11385). They have developed a centerfire block which is designed as a drop in replacement for your original rimfire block. S & S Firearms recently sent me samples of all their reproduction Spencer parts as well as their centerfire block. Their conversion is made entirely with new made parts. This includes the upper block which is machined from a solid billet of steel. Their design appears to be a simplified and improved version of the Hathaway centerfire block. There are only three internal parts; the firing pin, firing pin carrier and firing pin spring. One improvement is the use of a fully retracting firing pin. This means that the hammer does not have to be brought to half cock before opening the action. In previous centerfire conversions, when the hammer is all the way down, the firing pin protrudes beyond the face of the block. If the action is opened with the hammer down, the firing pin will drag across the primer and rim. Even worse, if the action is closed with a cartridge in the chamber, the firing pin could catch the rim and shear off. All of these problems have been eliminated in the S& S centerfire block. This block will work in any large frame Spencer. S& S Firearms also offers a reproduction rimfire block. This will accept an original firing pin and screw. If you wish to make your own centerfire conversion this would be an ideal starting point.

Original Spencer parts were made in lots, and then hand-fitted. So there is some variation in dimensions between lots. S & S has taken measurements from a large number of original breech blocks to determine the average dimensions. Their rimfire and centerfire blocks are machined to these average dimensions. Because of their precise tolerances these blocks will fit perfectly 95 percent of the time. The other 5 percent will require minor hand-fitting. Any competent gunsmith can handle this in short order. As an added note, they also have complete inner magazine tubes. These are made with a reproduction tube and spring with an original follower, follower screw and buttplate cap. This is so similar to the original that I had difficulty telling my original from their reproduction. They also offer an outer magazine tube (stock liner). Very useful if your original is badly rusted or the threads are stripped. S & S Firearms has taken great pains to make their reproduction parts identical to the originals, except with the centerfire block which is their own design. Just looking at their breech blocks, one can see the precision and attention to detail. Many machining operations are required to make one. Quality is top notch. As usual quality does not come cheap. But considering all the precision work involved, it certainly is a bargain. They also have a complete stock of original replacement parts for the Spencer as well as many other antique firearms. Their catalog is available for $2.00.

Now if you have a centerfire block, what are you going to shoot with it? Fortunately it’s not as difficult as you might think. The starting point is the .50-70 government case. These are available from several sources. Rim and base diameters are virtually the same for all Spencer cartridges. This means that they all can be formed from the same case.

To begin with, reduce the rim to .645”. This will be the same for all Spencer cartridges. Now trim to length. For the .56-56 centerfire trim to .875”. For the .56-50 centerfire trim to 1.155”. For the .56-46 centerfire trim to 1.075”. Next comes the tricky part - neck sizing. In the case of the .56-56 C.F. these will have to be opened up a bit you fireforming. Thinning of the neck may be necessary depending on the bullet diameter required. The .56-50 C.F. will be the easiest to form. Depending on the bullet diameter selected, the neck may require some expansion. Inside diameter of the neck will be about .515 diameter bullet so this is just fine. The .56-46 C.F. will be a bit tougher. This must be sized down to .475” and then fireformed to fill our the shoulder. The shoulder begins about .685” from the base. The sizing die should be brought down about .675” from the base in order to chamber the case. Due to the thickness of the case it may require several charges to fill out completely. After this operation is completed the neck will probably require reaming, again depending on bullet diameter required. One thing that is very important. After trimming to length and before any sizing is done, the cases must be annealed. If this is not done they will probably split upon foreforming. This goes for any of these cartridges as well as the reloadable rimfire cases. Because of variations from one gun to another the dimensions I’ve given here should be used as guidelines only.

Slug your bore and make a chamber cast. I can’t over-emphasize this. It is the only way to know exactly what size your cartridges should be.

The original rimfire cartridges were all loaded with 45 grains of black powder. Their hollow rims allowed for a bit more powder than can be used in the modified solid head .50-70 cases. However, these modern cases are much stronger and safer. Due to their construction they will only hold about 35-40 grains of FFG black powder. But this will depend on the bullet used.

Finally we come to the bullet. If you are shooting a .50 caliber Spencer you may be able to use a .50-70 mold of about 350 grains. The bullet can be sized down or the mold lapped out to suit. If you are lucky (like I was) the bullet may be fine as cast but this is not likely. A better alternative is to obtain a mold of proper size for your bore. There are several firms that offer molds for the black powder cartridge shooter. Northeast Industrial Inc., (2516 Wyoming St., El Paso, TX 79903) has a wide variety of molds. Rapine Associates (P.O. Box 234, RD 1, East Greenville, PA 18041) has molds for a number of black powder breech loading rifles and carbines.

If you have gone through all the trouble and expense of converting to centerfire and making suitable brass, the best alternative may be to obtain a custom mold. These are not much more expensive that production molds and they can be made to your exact specifications. The shape of original bullets are a little too pointed for safety with centerfire cartridges. If you decide to get a custom mold, the original design can be followed pretty closely. With the exception of the nose which should be rounded a bit to prevent accidental discharge in the magazine, bullet weight should be the same as originally used or perhaps slightly less to allow for a little more powder without an increase in overall cartridge length. Overall cartridge length is critical in the Spencer. If a cartridge is too long, it will not feed from the magazine to the breech block. Maximum cartridge length should not exceed 1.70” for any Spencer cartridge.

The Spencer was one of the most popular guns in America 120 years ago. In recent years its popularity has been returning. Thanks to its solid, sturdy design and large production, they are still pretty easy to find in good safe shooting condition. Between several antique gun parts dealers, virtually every original part is still available to keep them in good working order. Try finding spare parts for a gun that’s been obsolete for only 20 years. Good luck!

-webmaster's note- Kit Carson liked his Spencer- his rifle now resides in the museum in Taos, NM |

|

|

Putting life back into an old Spencer is indeed a rewarding task. Patience and diligence will pay off in X’s. However, before starting, have your Spencer checked over by a competent gunsmith. Then carefully construct your loads with black powder or Pyrodex only! As usual, I assume no responsibility for the loads listed above. They are given only as a guideline.

I hope I’ve shed some light on what may have been a dim subject. So go ahead, blow the dust off the Horizontal Shot Tower and let it speak again, Good luck!

First published in The Black Powder Report, Sept. 1985

-webmaster's note - Since this article was originally written there have been some gunmakers enter the market with modern-made Spencers. I have no personal knowledge of them but these are a few I have found. I believe I have probably left out some. If you are serious about shooting a Spencer you should consider a modern made one.

L. ROMANO RIFLE CO.

551 Stewarts Corners Rd Pennellville

NY 13132

(315) 695-2066

Builds complete Spencer Rifles and Carbines

****************

Spencer Rifle Co.

http://www.spencerrifle.com/

615 325 3551

****************

Armi Sport & Taylor’s

Co. Inc.

http://www.blockaderunner.com/Catalog/catpg3a.html

931-389-6294

Armi Sport & Taylor’s Spencer Reproduction